Polyurea Elastomer

Spray System

Tougher, longer-lasting protection

State-of-the-art polyurea

elastomer spray solution

Wide range of industrial uses

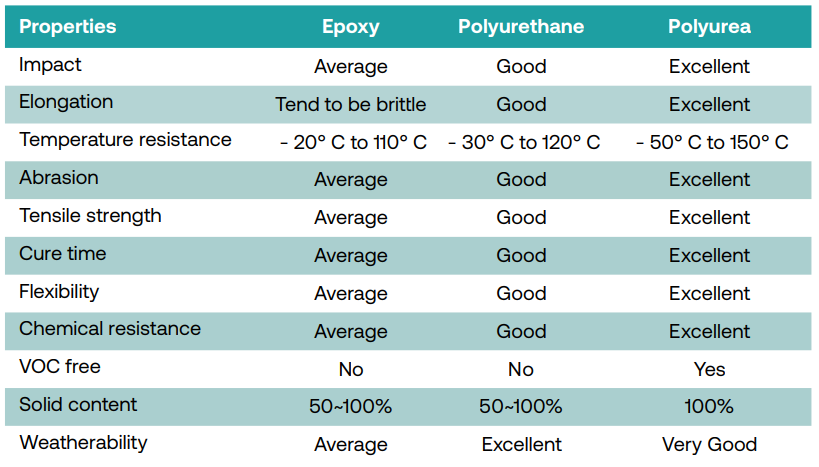

Offering many advantages over traditional alternatives such as conventional membranes, epoxy and standard polyurethane systems.

Whether utilised as a formulator, coating producer, or an applicator, with DuraPearl you can create spray systems with:

- Low emissions and low VOC – making the system a more sustainable alternative

- Fast cure capability depending on your specific needs

- Resilience to variable ambient outside temperature changes post application

- Total coverage with first application, reducing the need for multiple coats

- Unrivalled durability even in high temperatures up to 105 degrees celcius

- Excellent additive compatibility acceptance for adding pigments, fillers, etc.

- Stable reactivity profile – no catalysts required

DuraPearl – Polyurea

Elastomer Spray System

Any shape, any surface, any place

Wide range of applications

customised to your needs

| 1 Waterproofing 2 Roofs and surface coverings 3 Pipeline coatings 4 Joint and seam sealants 5 Fountains and pools 6 Concrete coatings 7 Floor coatings 8 Forklift ramps 9 Wood coatings |

10 Anti-slip coverings 11 Tank linings 12 Truck bed liners 13 Corrosion protection 14 Wear protection applications 15 Pallet protection systems 16 Oil and Gas infrastructure 17 Bridge protection 18Municipality and roading infrastructure |

Wide range of applications

customised to your needs

1 Waterproofing

2 Roofs and surface coverings

3 Pipeline coatings

4 Joint and seam sealants

5 Fountains and pools

6 Concrete coatings

7 Floor coatings

8 Forklift ramps

9 Wood coatings

10 Anti-slip coverings

11 Tank linings

12 Truck bed liners

13 Corrosion protection

14 Wear protection applications

15 Pallet protection systems

16 Oil and Gas infrastructure

17 Bridge protection

18Municipality and roading infrastructure

Benefits

Make the switch to DuraPearl Polyurea Spray Elastomer

Product Name

Other product information

Produced according to ISO 9001 and ISO 14001 standards

Pearl Polyurethane Systems is an ISCC certified company