Featured

Success Story

Project Details

Location: Dubai, United Arab Emirates

Project use: Multi–purpose exhibition building containing offices and F&B outlets

Year completed: 2020

Panel manufacturer: Emirates Industrial Panel (EIP)

Polyurethane core supplier: Pearl Polyurethane Systems

Pearl Fast Facts

Product: Metal sandwich panel insulation – rigid foam core

Features:

- Excellent fire properties (PIR)

- Insulation value

- Rigidity

- Durability

- Ease of handling

- Quick to fit

Effect:

- Increased efficiency

- Superior insulation properties

- Aesthetically pleasing

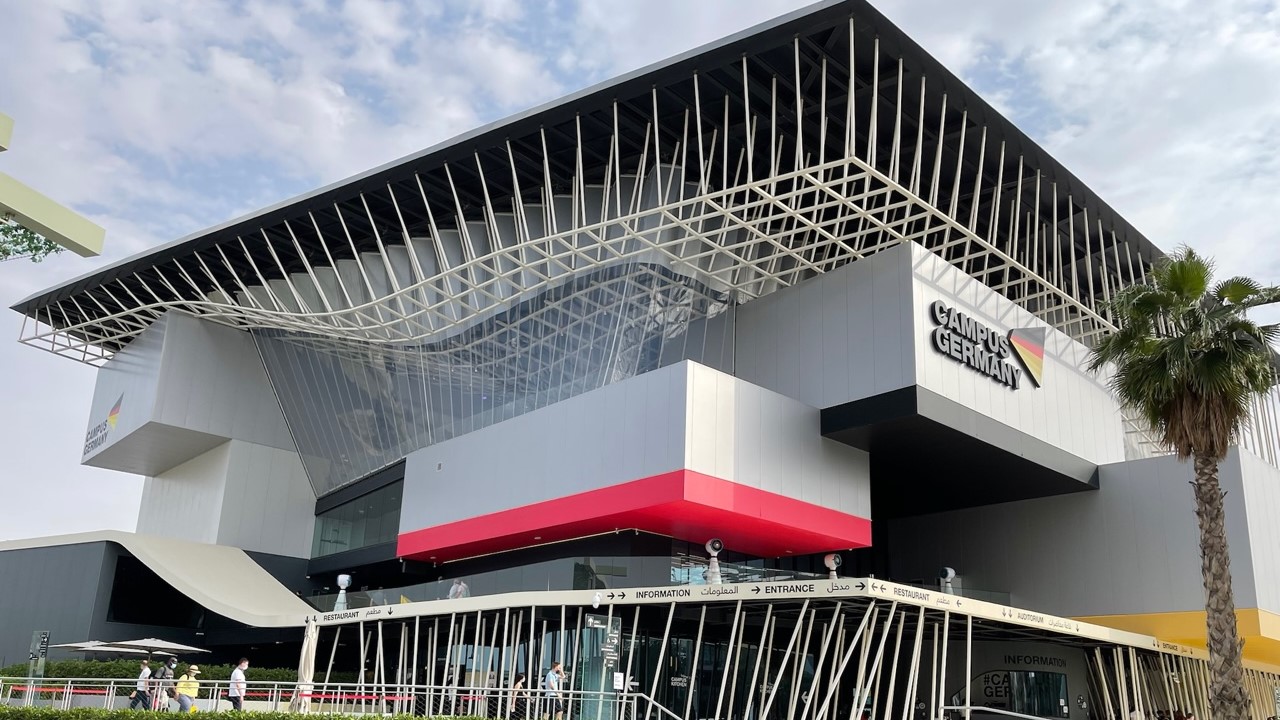

Campus Germany

Expo 2020 Dubai

German Pavilion

Advanced metal sandwich panel insulation containing polyisocyanurate rigid foam cores formulated and supplied by Pearl Polyurethane Systems

Installed on the vast German Pavilion at Expo 2020 Dubai

Expo 2020 Dubai

The main site of Expo 2020 Dubai is purpose-built precinct on a 438-hectare area (1083 acres), as large as 900 football pitches, located in the city of Dubai on the way to Abu Dhabi with three main themed districts; sustainability, mobility; and opportunity which are centred around the main event stage inside the focal point, Al Wasl Dome.

For the first time in World Expo history, every participating country has its own pavilion, with over 192 countries.

German Pavilion – CAMPUS GERMANY

The German Pavilion, known as CAMPUS GERMANY, was designed to be a forward-looking place of knowledge, research, and human interaction at the Expo 2020 Dubai. A range of sustainability-themed examples of innovation and ingenuity have been created to inspire visitors both young and old.

Building use

CAMPUS GERMANY features several interactive exhibits, special displays for children as well as information for adults, and a full-service restaurant.

The German Pavilion reflects the underlying campus idea. Rather than being a building in the traditional sense, it is a vertical ensemble of building volumes, surrounded by a connecting element with a central atrium at its heart.

Building insulation solution explained

Metal sandwich panels are insulating panels for residential, commercial, industrial, and a broad range of construction purposes. These sandwich panels consist of metal facings and an advanced PIR (polyisocyanurate) rigid core formulated by Pearl Polyurethane Systems and produced by Dubai-based panel manufacturer, Emirates Industrial Panel (EIP). This cladding product is lightweight and quick to fit, as well as offering excellent fire and smoke resistant properties.

An advantage is that these panels are thin and easy to handle which makes them one of the most cost-effective methods for building insulation, while creating a smooth and sleek effect that is aesthetically pleasing.

Why is polyurethane-based insulation more sustainable?

Buildings are responsible for over 40 percent of global energy consumption and more than one-third of greenhouse gas emissions. Energy lost through walls, roofs and windows is the largest single waste of energy in most buildings.

Polyurethane-based building insulation products provide a higher insulation value when compared to other comparable insulation materials such as mineral wool and fibreglass. Consequently, metal sandwich panels containing polyurethane are a more sustainable insulation solution due to the increased energy savings provided over a building’s lifespan.

What makes polyurethane insulation so attractive is its robust nature and longevity, meaning that metal sandwich panels last longer and do not need to be replaced as quickly as other insulation or cladding products – this reduces unnecessary wastage which has a positive impact on the environment and the effects of climate change.

Located in the Expo’s ‘Sustainability’ area, CAMPUS GERMANY’s ultimate client was the German Federal Ministry for Economic Affairs and Energy, while Koelnmesse was responsible for organisation and operations. Concept, planning and realisation of the German Pavilion was handled by the German Pavilion Expo 2020 Dubai Consortium, consisting of two companies, facts and fiction GmbH and NUSSLI Adunic. facts and fiction were responsible for concept, exhibition, and media design, NUSSLI Adunic for construction, while LAVA was responsible for the architectural implementation of the concept on behalf of the joint venture.